3D Reverse Engineering

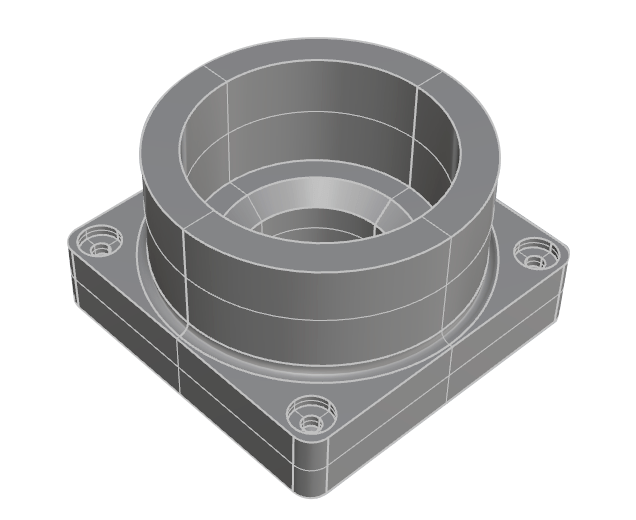

This technical term, 3D reverse engineering, refers to the process of converting a 3D scan into a CAD dataset with clean surfaces and geometries. It encompasses the reconstruction and remodeling of objects into CAD models. The precision requirements for reverse engineering vary depending on the intended use. Distinctions are made between technical applications that demand high precision and visual 3D models that primarily serve optical purposes.

We are currently witnessing an industrial revolution driven by digitization through 3D scanners and additive manufacturing. Within this context, reverse engineering plays a crucial role. If you are interested in the application of 3D reverse engineering in the field of additive 3D printing, then this post is tailored to your needs. The Mako-Technics team provides in-depth insights on this topic.

Looking to accelerate your progress? Reach out to the experts at Mako-Technics directly.

3D Reverse Engineering: Applications

Through reverse engineering, we obtain the necessary specifications for components, enabling us to reproduce hard-to-obtain parts using 3D printing technology. It also proves beneficial when you need to optimize a part or object for which no digital model is available. In such cases, we scan the object and make design modifications accordingly, saving you considerable time.

Require a CAD model of an existing object? No problem! We offer digitization services. By utilizing a 3D scanner, we capture the specific part and convert it into a digital file. Subsequently, we create the CAD file, allowing for modifications or complete redesigns. This technique empowers us to leverage professional 3D printers for additive manufacturing, resulting in reduced production costs and time savings.

For optimal results, we employ highly precise capture techniques to ensure all relevant details are preserved for replication. Our reliance on cutting-edge 3D scanning technologies guarantees the creation of accurate and detailed three-dimensional models.

3D Reverse Engineering for Additive 3D Printing: A Service by Mako-Technics

Mako GmbH, based in Germany, is known for employing state-of-the-art software and tools in the field of 3D reverse engineering. From the CAD file provided by us, we proceed to print your component. We rigorously test any modifications and optimizations made to ensure quality and performance. By doing so, you can reduce production errors and streamline your processes. Additionally, this approach allows for the restoration and testing of surfaces that lacked prior digital data.

Our engineers are renowned specialists in 3D reverse engineering, delivering exceptional quality made in Germany. Benefit from our extensive experience and contact us today! For further insights into our company, reverse engineering, or the industry at large, we invite you to visit our blog. There, you will find regular posts covering a wide range of relevant topics.