Reverse Engineering and 3D Printing

We have already devoted ourselves extensively to the subject of reverse engineering for 3D printing in another article. Reason enough for the Mako GmbH team based in Germany to look at the whole thing from the practical side today. How can reverse engineering and 3D printing be combined? Where can reverse engineering offer practical solutions? How can this increase the speed and productivity of companies? In this article we give you practical examples of this.

Reverse engineering and 3D printing: practical solutions

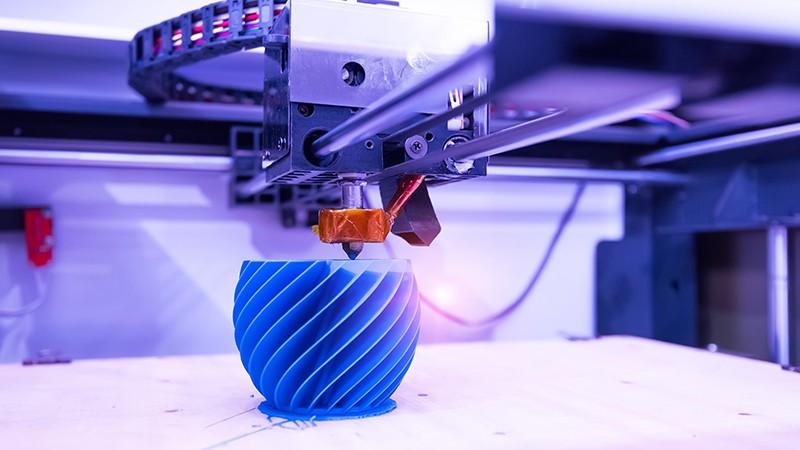

The combination of remodeling with 3D printing has proven to be an integral part of the development workflow. To give you an example of this, let’s take a mental look at the aerospace industry.

Some manufacturers routinely make reverse engineered parts and 3D prints of old aerospace parts. This enables safe production of these parts. These very accurate and traceable prototypes are used for much more than just shape and fit.

New solutions

New and portable measurement solutions enable non-critical components to be redeveloped in the shortest possible time. In this way, these can also be modeled, reproduced, tested and finally installed again extremely quickly. We are happy to give you an example of this in the following. An example from the same field of application – aerospace.

Parts often need to be replaced on older aircraft. In many cases, however, spare parts are no longer available here. Just as little CAD data or original tools. Airplanes have a long service life. After such a long period of use, in some cases the former construction tools no longer fit perfectly with the actual components. For example with pipelines.

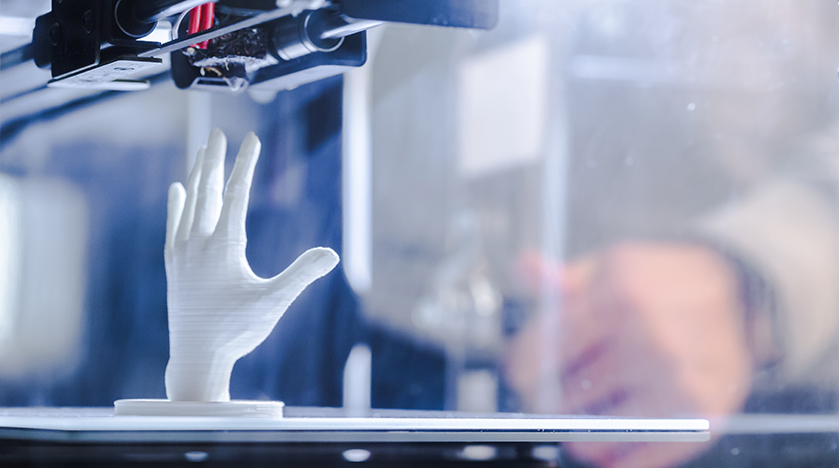

Sometimes it also happens that a component has a defect in its construction. Reverse engineering and product realization offer engineers effective help in identifying problem areas. And to apply recommended solutions for this. In this way, components that are usually manufactured in many weeks can be produced in just a few days. As a highly accurate model.

This model can then be subjected to a fit test. The client can subsequently approve the relevant part for production.

Once the design has been checked and approved, the 3D prototype can be used as a representative model for all subcontractors within the production chain.

Reverse engineering and 3D printing of Mako GmbH

If you need reverse engineering experts, look no further. You found it. The Mako-Technics team is considered a specialist in the field of remodeling. Make us a strong partner by your side. Contact us! Together we will find a solution.

We would be happy to provide you with a free sample of our work if required.

Are you interested in other topics related to us and reverse engineering? Then visit our blog! In this, we offer you informative added value with a wide range of articles on everything to do with the industry.