Reverse Engineering for 3D Printing

Reverse engineering allows you to completely rethink and improve your production process. Developing new solutions is often not an easy task. This usually takes a lot of time. This is where 3D technologies can help you effectively. In this article, the Mako GmbH team, based in Germany, explains how you can use reverse engineering for 3D printing to optimize your products and their manufacturing process.

Reverse engineering and 3D printing: what is remodeling?

Reverse engineering or remodeling is a learning method with which individual objects are taken apart. This enables users to better understand how these were produced. And then recreate you.

But that is not the only purpose. Reverse engineering also gives you a lot of details about the original manufacturing process. This also gives you the option of subsequently optimizing components or objects. This is exactly how you can revise the process and make it more effective. So remodeling helps in different areas.

2 complementary methods: 3D printing and reverse engineering

The use of 3D technologies in remodeling brings users a number of advantages. Product development and prototyping can be significantly improved. This increases the quality of the end products. 3D printing and 3D scanning are the most important methods for reverse engineering.

The conversion of objects into 3D models

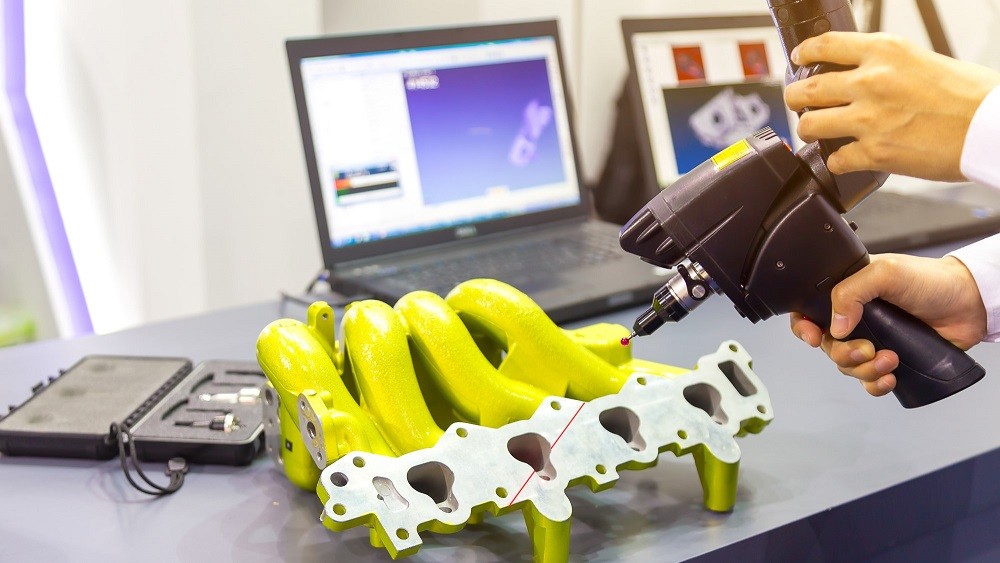

3D scanning is ideal for examining an object. This gives you a precise picture of the digitized reality. In simple terms, 3D scanners create digital network representations of your object, consisting of triangles. Since CAD programs are not particularly precise, they do not work with network objects.

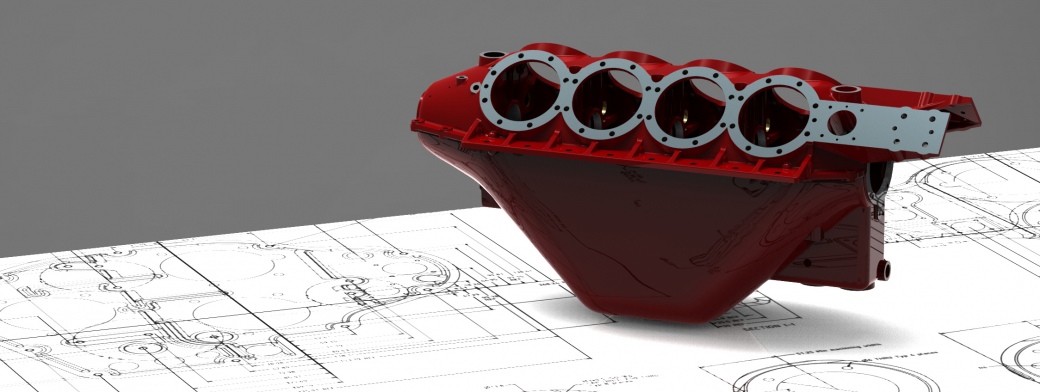

Have you scanned your object? And now you have a precise 3D model? Then you can now make all the necessary optimizations. CAD and 3D modeling software allows you to carry out various stress tests. In this way, the behavior of different parts can be determined beforehand. This enables problems and weak points to be identified. A clear added value compared to conventional methods.

The development phase of your products can be effortlessly shortened from many weeks to a few days using 3D scans and CAD software.

Reverse engineering and 3D printing: develop prototypes much faster

With additive manufacturing, you can adapt your model quickly and efficiently. This means that it can also be produced in a much shorter time. 3D printing is an extremely fast and, above all, reliable method of production that allows you to choose between different technologies and materials.

Remodeling enables detailed examination of parts or objects. This shows the original manufacturing methods. This will give you information on how to improve and customize the property in question.

3D printing is also of great importance for the production of prototypes. The choice of different materials makes it so versatile. Users can freely choose from various resins, plastics or metals. This means that products can be manufactured much faster and at lower cost.

3D printing: Not only suitable for making prototypes

In the area of rapid prototyping, additive manufacturing technologies are extremely well-proven. For this, however, a long, rocky road had to be covered. Reverse engineering in combination with 3D printing enables you to produce fully functioning parts. This is how you can optimize your production process. Cost reductions included.

We hope that we were able to demonstrate the advantages of reverse engineering in 3D printing to you in this article. Do you have further questions about this or about us? Please do not hesitate to contact us! Simply use our contact form for this. The Mako-Technics team looks forward to your message.

Would you like to find out more about us and reverse engineering? Then visit our blog! There you will regularly find new information and topics about us and the industry.